Pipe Bursting

Trenchless technology Overview

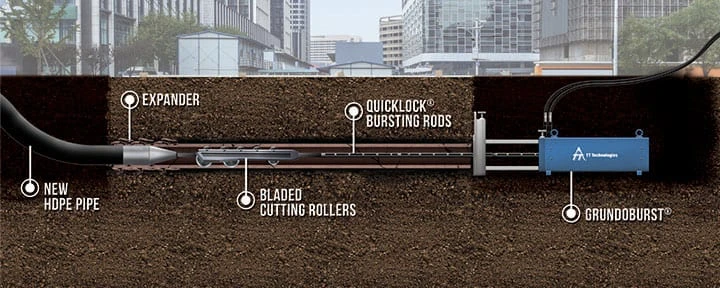

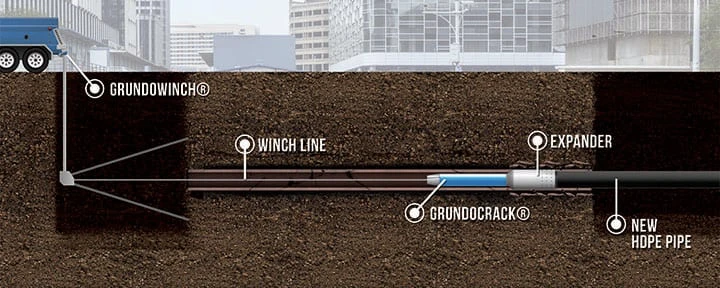

Pipe bursting is a common form of pipeline rehabilitation that involves replacement of the existing host pipe utilizing trenchless technology. The installation process involves fracturing or splitting the existing pipeline using a bursting head or cutting tool while simultaneously installing a new, similarly sized pipeline inside the cavity previously occupied by the former pipeline. A static or pneumatic cutting tool can be used to fracture the existing host pipe and the new pipe is installed using a winch or hydraulically actuated rod puller.

Pipe bursting can be used to rehabilitate pipelines ranging in size from 2 inches to 54 inches in diameter and in sections up to 1,000 LF in length. In select circumstances, it is possible to increase the diameter of the pipeline by upsizing the new piping material. Depending on soil conditions and pipeline depth, pipe bursting can cause ground movement which can impact adjacent underground infrastructure or potentially damage aboveground improvements like roads, sidewalks, curb, etc.

Pipe bursting is a great trenchless solution for rehabilitating gravity sanitary or storm sewers. It can also be used in pressure pipe applications like water and sewer force mains.

Fracturable materials such as cast iron, PVC, reinforced concrete pipe (RCP), vitrified clay pipe (VCP) and asbestos cement (AC) pipe are good candidates for installing size-on-size or potentially upsizing with new piping material using static bursting tools and expanders. Non-fracturable materials such as ductile iron, steel and HDPE are also able to be bursted using specially designed cutting or splitting tools. Behind the bursting head is an expander that forces the material fragments and displaced soil outward allowing for the new pipeline to immediately fill the open void.

In recent years, HDPE and PVC pipe are amongst the most common types of new piping materials used for pipe bursting.

Typically, the rehabilitation solution requires that the pipeline alignment be straight. It is possible to rehabilitate up to 1,000 LF of pipelines each day with this installation process.

In summary, pipe bursting is a useful trenchless rehabilitation solution if the soil conditions are appropriate, the alignment is straight and adjacent utilities are not in close proximity to the existing pipeline.

Pipe Bursting- Capabilities

- Diameter Range: 1″ – 54″ (HDPE) / 4″ – 36″ (FPVC)

- Maximum Installation Length: 1,000 LF

- Maximum Temperature: 180deg F (HDPE Raised Temp) / 140deg F (FPVC)

- Pressure Rating: 335psi (HDPE) / 305psi (FPVC)

- Liner Wall Thickness: Based on Dimension Ratio (DR)

- Direction Changes: None

- Cost: $-$$

- Roughness Coefficient: 150 (HDPE) / 150 (FPVC)

Pipe Bursting- Strengths & Weaknesses

Inexpensive w/ Widespread Availability

Speed of Installation

Potential Ground Movement

Inability to be Pulled Through Bends