A cost-saving alternative to pipe replacement isn’t just a pipe dream.

Pipe Lining Product Recommendations

The fact of the matter is that ALL rehabilitation solutions have inherent strengths and limitations. The cost of these trenchless technology pipe lining systems can vary greatly depending on each application. Gemini Pipeline Rehabilitation Solutions, LLC are pipe restoration experts and have experience with a multitude of pipe lining products, installation methods & technologies.

First, we develop a thorough understanding of the project’s requirements, review the condition of the existing pipeline and then make unbiased recommendations that matches the specific needs of each project on a case-by-case basis. Gemini specializes in helping pipeline owners’ assess their options, identify the best course of action and execute projects successfully so that their piping will remain trouble-free for decades to come.

On each project, our primary goal is to manage the rehabilitation of our clients’ pipelines to reduce project costs by the maximum extent possible. We are independent management consultants who work alongside reputable 3rd party trenchless technology providers, pipe lining contractors, and suppliers to provide lining solutions that best fits our client’s needs.

Pipeline Product Selection Consideration Factors:

- Pressure Handling Capabilities

- Flow Requirements

- Temperature Rating

- Pipeline Alignment & Bends

- External Forces

- Useful Life

Pipe Lining Products

Pipe Lining Solutions | How it Works |

|---|---|

Pressure & Non-Pressure Rated | Involves inserting a resin-saturated felt tub in the host pipe. After the tube has been installed inside the existing pipeline, it is then pressurized and cured. |

Pressure Rated | Involves using a bursting tool attached to the front of new pipe that is pulled through and simultaneously breaks apart the existing host pipe. |

SIPP (Spray-In-Place) Pressure & Non-Pressure Rated | Involves spraying a coating onto the inside wall of the host pipe. |

Pressure Rated | Involves installing a smaller diameter liner pipe inside a large diameter host pipe. Types of liner pipe materials include HDPE, PVC, FRP, nylons, composite piping, fire hose style liners, steel, and more depending on operational requirements & budget. |

Compressed Fit or Swagelining Pressure & Non-Pressure Rated | Involves radially compressing liner pipe that has a diameter equal to or larger than the inside diameter of the host pipe with a static die or roller reduction box. While the liner is compressed, it is pulled through the host pipe. Note: HDPE is the most common material but Nylons and other materials are available for high temperature applications. |

Product Capabilities

Pipe Lining Solutions | Diameter Range | Line Thru Bends | Maximum Installation Lengths | Relative Cost | Pressure Rating | Market Sectors |

|---|---|---|---|---|---|---|

2" to 120" | Yes | Up to 1,200' | $-$$$ | 250psi | Water, Sewer, Residential, Industrial | |

Up to 54" | No | Up to 1,000' | $-$$ | 335psi | Water, Sewer, Industrial | |

SIPP | 6" and Larger | Yes | Up to 500' | $-$$ | TBD | Water, Sewer, Residential, Industrial |

2" to 126" | Dependent on Material Selection | Up to 8,500' | $-$$$$ | 3,000psi | Water, Sewer, Oil & Gas, Mining, Industrial, Offshore | |

Compressed Fit or Swagelining | 2" to 63" | LR Sweeps Only | Up to 3,000' | $-$$$ | 125psi | Water, Sewer, Oil & Gas, Mining, Industrial, Offshore |

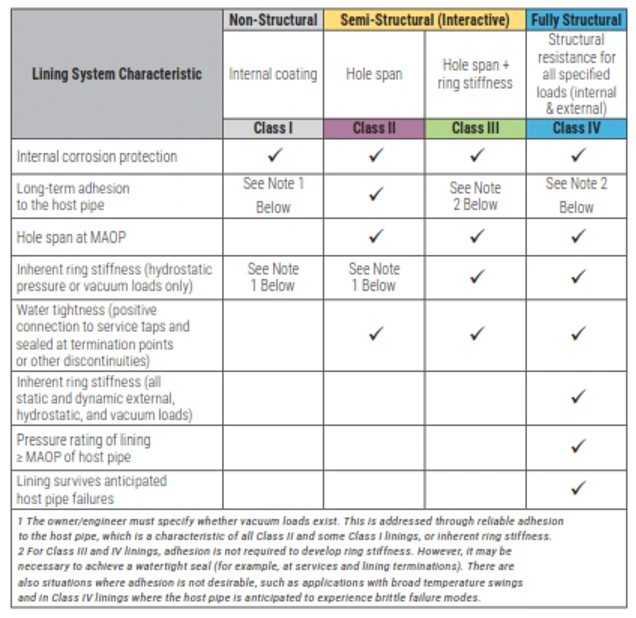

Lining Systems Classifications Chart

Product Selection Consideration Factors:

- Pressure Handling

- Capabilities

- Flow Requirements

- Temperature Rating

- Pipeline Alignment &

- Bends

- External Forces

- Useful Life