COMCD Del City Raw Water Pipeline Rehabilitation Abstract:

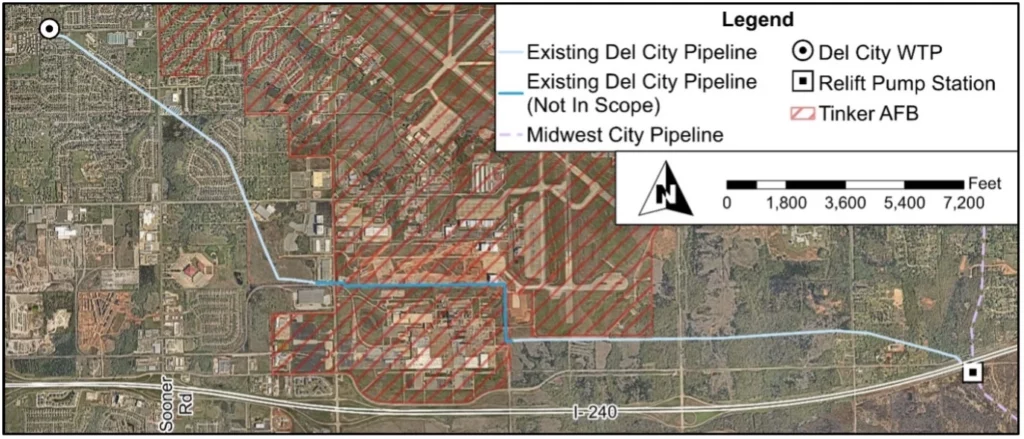

This NASTT paper will review the Del City Pipeline improvement project which included rehabilitating 9,200 linear feet of 18-in, 21-in, and 24-in reinforced concrete piping with a compressed fit HDPE liner system installed by Aegion Corporation. The raw water pipeline traveled under an interstate, around an Air Force Base, through busy residential neighborhoods and across several roadways. The engineer, Alan Plummer Associates, Inc., reviewed several trenchless rehabilitation technologies but settled on a compressed fit liner because of the system’s cost effectiveness, ability to be installed in several thousand-foot lengths and the speed at which the system can be installed. The HDPE liner was designed for a 90-psi operating pressure while offering a fully structural (AWWA Class IV) rehabilitation solution. The entire project required a total of nine pull sections with the longest continuous pull section totaling over 2,500 linear feet.

Project Challenges

The project team was challenged with continuously supplying drinking water to the City’s residents during construction by coordinating shutdowns & replenishment period and utilizing the water treatment plants limited storage capacity which eliminated the need to construct a temporary bypass system. The project was successfully completed over a seven-month period despite some of the worst winter weather in the City’s history. All this work took place without the residents knowing that the pipeline supplying the area’s drinking water was being upgraded with a trenchless rehabilitation solution that has a lifespan of greater than 50 years.